WHY USE FIBERGLASS COMPOSITES

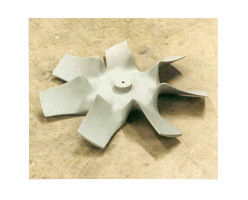

Light Weight |

|

Energy Consumption |

Parts Consolidation |

|

High Strength |

Low Tooling Cost |

|

Corrosion Resistance |

Design Flexibility |

|

Low Finishing Cost |

Molding Flexibility |

|

Dimensional Stability |